Izintambo zekhebula le-BLMT ezinamabhawudi okugunda

Izintambo zekhebula le-BLMT ezinamabhawudi okugunda

1. Uhlolojikelele lomkhiqizo

Igama lomkhiqizo: I-Torque Terminals (uchungechunge lwe-BLMT)

Indlela yokumelela imodeli

I-BLMT- □ □/● □

I-BLMT-diameter ye-recess ekhwezayo/imodeli ye-conductor efanelekayo yohlu lomkhiqizo

2. Isicelo

Amatheminali e-Torsion yizixhumi ezisetshenziselwa ukuxhuma izintambo kumishini, ikakhulukazi ezisetshenziselwa ukuxhuma izintambo ezivaleleke, izintambo ze-aluminium, izintambo ze-aluminium alloy, izintambo ze-steel-core aluminium kanye nezintambo zethusi ezindaweni ezingathwele.

3.Sukubhekana kwe isicelo

Umugqa oholayo osebenzayo: 25-240㎜².

4.Imingcele yezobuchwepheshe

①Umzimba womkhiqizo wenziwe ngamandla aphezulu we-aluminium alloy ye-tin-plated

②Indawo engaphakathi yembobo yocingo inedizayini ye-groove enentambo

③Amabhawodi e-torque asebenzisa ukwakheka okuphindwe kabili kwekhanda lokugunda ukuze kuqinisekiswe ukuthi ibhawodi ayikwazi ukususwa ngemva kokusika ikhanda, phansi kwebhawodi kunendandatho yokuxhumana, iqinisekisa kangcono izakhiwo zikagesi zomkhiqizo.

④Ngephedi elikhethekile, likhiphe noma ulifake, futhi ulungise ububanzi bomkhiqizo wezintambo ezisebenzayo, imikhiqizo emithathu izoqinisekisa ukuthi zonke izintambo ezisuka ku-25㎜²-240㎜² ziyasebenza

5. Izinyathelo zokufaka

①Hlola uhlobo nobubanzi bentambo bese ukhetha uhlobo olufanele lwetheminali yetorque ukuze unqume ukuthi intambo yephedi iyasetshenziswa yini.

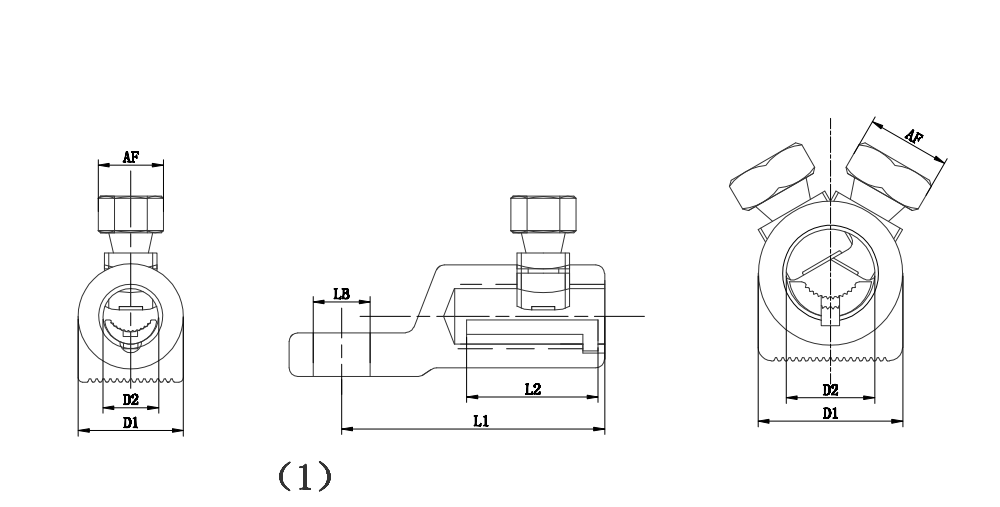

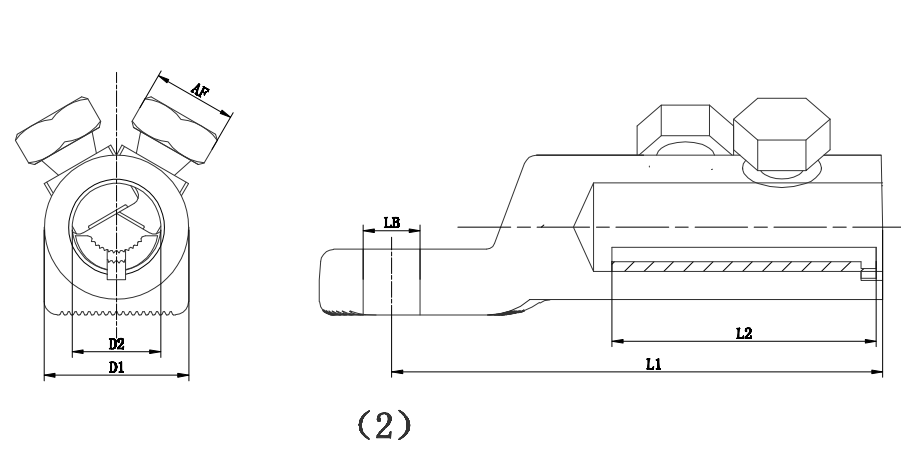

| Ikhathalogi No. | I-Conductor Efanelekayo mm² | Ububanzi (mm) | Ukuma kanye nobubanzi bembobo efakwayo | Inombolo yeBlot. | Ukucaciswa kwekhanda lomshudo | Ubude bokuhlubula | |||

| L1 | L2 | D1 | D2 | ||||||

| I-BLMT-6/50-13 | 6-50 | 50 | 20 | 18 | 10 | 13 | 1 | 13 | 25 |

| I-BLMT-25/95-13 | 25-95 | 60 | 30 | amashumi amabili nane | 12.8 | 13 | 1 | 13 | 34 |

| I-BLMT-25/95-17 | 25-95 | 60 | 30 | amashumi amabili nane | 12.8 | 17 | 1 | 13 | 34 |

| I-BLMT-35/150-13 | 35-150 | 86 | 36 | 28 | 15.8 | 13 | 1 | 17 | 41 |

| I-BLMT-35/150-17 | 35-150 | 86 | 36 | 28 | 15.8 | 17 | 1 | 17 | 41 |

| I-BLMT-95/240-13 | 95-240 | 112 | 61 | 33 | 20.2 | 13 | 2 | 19 | 70 |

| I-BLMT-95/240-17 | 95-240 | 112 | 60 | 33 | 20 | 17 | 2 | 19 | 70 |

| I-BLMT-95/240-21 | 95-240 | 112 | 60 | 33 | 20 | amashumi amabili nanye | 2 | 19 | 70 |

| I-BLMT-120/300-13 | 120-300 | 115 | 65 | 37 | amashumi amabili nane | 13 | 2 | amashumi amabili nambili | 70 |

| I-BLMT-120/300-17 | 120-300 | 120 | 65 | 37 | amashumi amabili nane | 17 | 2 | amashumi amabili nambili | 70 |

| I-BLMT-185/400-13 | 185-400 | 137 | 80 | 42 | 25.5 | 13 | 3 | amashumi amabili nambili | 90 |

| I-BLMT-185/400-17 | 185-400 | 137 | 80 | 42 | 25.5 | 17 | 3 | amashumi amabili nambili | 90 |

| I-BLMT-185/400-21 | 185-400 | 137 | 80 | 42 | 25.5 | amashumi amabili nanye | 3 | amashumi amabili nambili | 90 |

| I-BLMT-500/630-13 | 500-630 | 150 | 95 | 50 | 33 | 13 | 3 | 27 | 100 |

| I-BLMT-500/630-17 | 500-630 | 150 | 95 | 50 | 33 | 17 | 3 | 27 | 100 |

| I-BLMT-500/630-21 | 500-630 | 150 | 95 | 50 | 33 | amashumi amabili nanye | 3 | 27 | 100 |

| I-BLMT-630/800-13(eyenziwe ngokwezifiso) | 630-800 | 180 | 105 | 61 | 40.5 | 13 | 4 | 19 | 118 |

| I-BLMT-630/800-17(eyenziwe ngokwezifiso) | 630-800 | 180 | 105 | 61 | 40.5 | 17 | 4 | 19 | 118 |

| I-BLMT-800/1000-17 | 800-1000 | 153 | 86 | 60 | 40.5 | 17 | 4 | 13 | 94 |

| I-BLMT-1500-17 (eyenziwe ngokwezifiso) | 1500 | 200 | 120 | 65 | 46 | 17 | 4 | 19 | 130 |

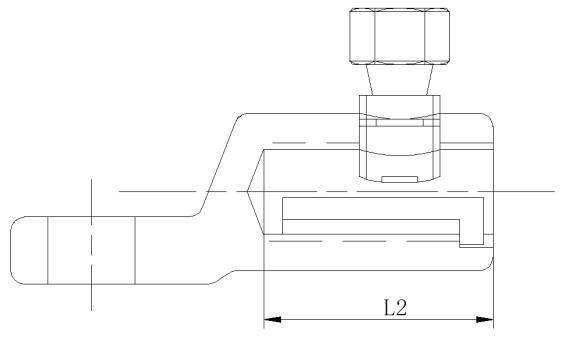

②.Ukulinganisa ubude bomgodi wangaphakathi womqhubi wokugcina, ukucacisa ubude bekhasi lentambo (ubude bomqhubi wangaphakathi wembobo engu-L-wire peel ubude L2≤2 mm).

③Faka intambo kutheminali bese ufake iokomshiniibhawodi.

④Sebenzisa amandla ngesikrufu sesokhethi kuze kunqanyulwe ikhanda le-torque bolt.

⑤Sebenzisa amabhawodi afanelekile ukuze uvikele izintambo zekhebula likaMechanical kumishini.

6.Izici Nezinzuzo

▪ Uhlu olubanzi lwezinhlelo zokusebenza

▪ Umklamo ohlangene

▪ Ingasetshenziswa cishe nanoma yiluphi uhlobo lwekhondatha nempahla

▪ Amantongomane ekhanda eshear e-torque aqinisekisa ukusebenza kahle kokuthinta ugesi

▪ Ukufakwa kalula kusetshenziswa izikrufu zesokhethi ezijwayelekile

▪ Eyakhelwe kusengaphambili ukuze ifakwe kahle kakhulu kumakhebuli kagesi aphakathi nendawo afika ku-42kV

▪ Ukumelana nokushaqeka okuhle kokudlulela ngokweqile kanye nesikhathi esifushane

I-lugbody yenziwe nge-high tension aluminium alloy. Amatheminali afanele ukusetshenziswa kwangaphandle nangaphakathi futhi atholakala ngamasayizi ahlukene wokuvula amasundu.

Uhlobo lwebhawodi lomshini1

Enziwe nge-aluminium alloy ekhethekile, lawa mabhawodi okuxhumana angama-hexagon head double shear head bolts. Ama-bolts aphathwa nge-lubricant yekhwalithi ephezulu futhi afakwe indandatho ekhethekile yokuxhumana. Lawa mabhawodi okuxhumana awakwazi ukususwa uma ikhanda lebhawodi selisikiwe.

Uhlobo lwebhawodi lomshini2

I-screw tooth ye-torsion bolt yakhelwe ngezigaba ezine, ukuze ukuphuka kocingo lokuqinisa ukufakwa kucwiliswe ebusweni bepayipi elixhumayo, Ibhawodi elinomklamo we-hexagon wangaphakathi, Susa ibhawodi ngesikhathi sokulungiswa,Umzimba ungasetshenziswa ngokuphindaphindiwe, Yehlisa izindleko zokwakha

Izesekeli

Izesekeli ezikhethekile, ngaphakathi nangaphandle zingalungisa uhla lwekhondatha olusebenzayo. Lawa ma-plug-in anemigqa yobude kanye nendawo yokubeka indawo.

Ukufakwa

▪ Ayidingi amathuluzi akhethekile ukuze ifake, kungafakwa isikrufu sesokhethi kuphela;

Ubude obufanayo bokuncishiswa bohlobo ngalunye, okuhlanganisa nokuhlinzekwa kokufakiwe;

Ukuklanywa kwamantongomane ekhanda esikele se-torque ukuqinisekisa ukuthintana okuthembekile nokuqinile;

▪ Ijoyinti ngalinye noma isikhwama sekhebula sinomyalelo wokusifaka;

▪ Sincoma ukusebenzisa ithuluzi lokusekela (bona okunamathiselwe) ukuze uvimbele ukugoba komqhubi.

▪Isokhethi engu-Hexagonal enobukhulu obulungile be-A/F

▪Isikrufu se-ratchet Noma isikrufu somthelela kagesi

Noma isikrufu somthelela kagesi

▪Kuyanconywa kakhulu ukusebenzisa i-clamp ukuze kusekelwe amabhawodi okugunda ngesikhathi sokugunda kanye nokuvikela ukugoba kukakhondakta.